In this live session, let discuss some points related to using Naphtha as fuel gas, moreover you will learn how to show and configure PFD table on Aspen HYSY.

- Learn Aspen HYSYS today: find your Aspen HYSYS online course on Udemy.

- Analyzing the Impact of Feed Changes on the Crude Distillation Unit. Aspen HYSYS, with its ability to rigorously simulate refinery wide processes & equipment including distillation columns, reactors, heat exchangers, gas plants and more, enables refiners to quickly.

Upon successful completion of this course, you will be able to:

Upon successful completion of this course, you will be able to:- Build and optimize steady state simulation models

- Define and manage crude oil assay information and properties

- Generate rigorous heat exchanger models from Aspen HYSYS to produce the most optimal designs at the right economics

- Model pipeline networks and mitigate the risk for flow assurance issues

- Design, revamp and debottleneck process equipment

- Troubleshoot common convergence problems and use best practices

Audience:

Anyone who needs a flexible & effective way to master Aspen HYSYS fundamentals at their own paceTraining Details

Course Id:

EHY101 Online Class

Duration:

3 day(s)

CEUs Awarded:

2.1

Level:

Introductory

Benefits

- Fully online. Our online classes are designed for flexibility. This allows you to plan your study time to fit your schedule.

- Learn from anywhere. No travel required.

- Practical skills learned through hands-on, self-paced workshops

- Guidance from a live instructor

- Exchange ideas with classmates and instructor through online discussion boards

- Class prepares you for the Aspen User Certification exam

Pre-requisites

A background in chemical/process engineering, oil/gas industry, or in petroleum refiningSubsequent Courses

- EHY202 Advanced Solutions using Aspen HYSYS

- EHY223 Aspen HYSYS Dynamics: Introduction to Dynamic Modeling

- EHY121 Building MS Excel User Interfaces for Aspen HYSYS Simulations Using Aspen Simulation Workbook

Agenda

Each week starts with short, online instruction by a live expert through a web meeting. The rest of the week is self-paced. Students exchange ideas, get help and interact with the class & instructor through an online discussion board. The online discussion board is open throughout the class and is monitored by the instructor during fixed hours.Week 1:

Aspen Hysys Online

Week 2:Week 3:

Aspen Technology, Inc. awards Continuing Education Units (CEUs) for training classes conducted by our organization. One CEU is granted for every 10 hours of class participation.

The Aspen Icarus Family

Integrated economics is a new feature in Aspen HYSYS® (HYSYS) that enables process engineers to rapidly estimate the relative capital and operating costs in their process modeling studies using Aspen HYSYS. This feature brings the benefits of the Aspen Economic Evaluation product family (the Aspen Icarus family) to the process simulation environment. The Aspen Icarus family includes:

- Aspen Process Economic Analyzer (formerly known as Icarus Process Evaluator)

- Aspen Capital Cost Estimator (ACCS)

- Aspen In-Plant Cost Estimator

The new costing module evaluates economics based on Icarus technology. The approach used in the technology doesn’t rely on capacity-factored curves for equipment sizing, nor does it rely on factors to estimate installation quantities and installed cost from bare equipment cost. Instead, it follows industry-standard design codes and procedures to represent equipment with associated plant bulks, and cost modeling and scheduling methods to estimate the cost of project.

The main steps in the integrated economic evaluation are as follows:

- Activating the costing engine

- Mapping unit operations to equipment

- Sizing equipment

- Economic evaluation and reviewing results

The Mapping and Sizing steps can be individually performed or can be skipped in favor of an “Auto Evaluation” based on default-assigned mappings and sizing algorithms.

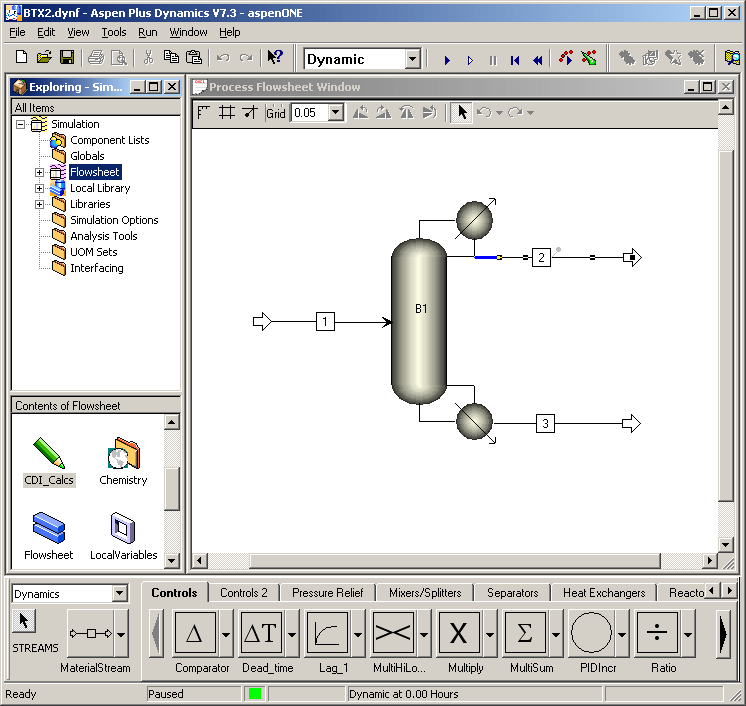

Figure 1: Economic Evaluation Tab in Aspen HYSYS Simulation Environment

Activating the Costing Engine

The costing engine is Aspen Process Economic Analyzer (APEA). By activating the economic module, the Aspen HYSYS simulation results automatically transfer to APEA. The module develops estimates based on a “standard basis file” which includes company-standardized, project-standardized, and the geographic cost basis (US Gulf Coast, Europe, Middle East, UK, and Japan) information.

Mapping Unit Operations to Equipment

A key step in economic evaluation with the new integrated evaluation feature is the mapping of each simulator model (unit operation) to one or more process equipment. For example, a distillation column in Aspen HYSYS might be mapped into several items such as a trayed tower, a kettle-type reboiler, an overhead condenser, a reflux pump, and a horizontal drum (Figure 2). The new workflow has both the ability to automatically establish “default” mappings as well as the capability to over-ride these mappings and substitute the user’s own mappings. The user can change, remove, and add equipment during the mapping process.

Aspen One Hysys

Sizing Equipment

Sizing of the equipment is performed using the available simulation data and the default sizing procedure; missing data is estimated by the system. The default material of construction for all equipment is carbon steel. Users can review the sizing and materials of construction and override estimated sizes, revise material of construction, and enter values for unsized equipment.

Economic Evaluation

The Economic Evaluation module develops both capital cost and utility cost. The following costs have been considered for the calculation of the project capital cost:

Direct Costs which refers to material costs and labor costs for:

- Equipment and Setting

- Piping

- Civil

- Structural Steel

- Instrumentation and controls

- Electrical equipment and materials

- Insulation

- Paint

Indirect Field Costs

- Engineering and supervision, Start-up and commissioning

- Construction expenses - Fringe benefits, Burdens, Insurance, Scaffolding, Equipment Rental, Field services, temporary constructions, etc.

Indirect Non-Field Costs

- Freight

- Taxes and permits

- Engineering - Basic engineering, Detailed engineering, and Material procurement

- Contingency - allowances for unpredictable events

- Other project costs - General and Administrative expenses, Contract fees, Home office expenses

The utility cost of a project is determined by the Economic module based on the appropriate process utility fluids selected either by the user or by the Sizing Expert from the list of 21 default utility streams already present in the system. Once the utility resources are selected, the utility cost for every utility resource used in the project is determined during the operating cost evaluation.

The results of the economic evaluation and the equipment summaries can be created in Excel format as a complete project economic report. The summary and detailed results can be reviewed in order to study the feasibility of the design and to compare process alternatives.

Contingency (defined based on specified process description, process complexity, and project type), process control, location, engineering start date, soil conditions, vessel design code, and level of instrumentation are the general specifications affecting capital and operating costs. The costing scenario created by Aspen HYSYS can be opened directly by Aspen Process Economic Analyze (APEA) or by Aspen Capital Cost Estimator (ACCE) for further development, define a custom model for sizing equipment, or tuning of the cost estimate.

Aspen Hysys Online

Summary

In general, the new feature will be of interest to many HYSYS users due to its functionality in reasonable cost estimation of a project through a simple system and in providing a way to study process alternatives from an economic point of view early in the process design. However, it should be noted that the sizing and the cost evaluation of a project are performed using default methods and procedures and missing data is estimated by the system. So, if the user enters more detailed information in the system based on the design criteria and the scope of the project, the estimated cost of the project would be more accurate.

References

1. “Aspen Process Economic Analyzer V7.0 User Guide”, Aspen Technology Industry (July 2008).

2. D. McCarthy, R. Beck, and G. Dissinger, “Getting Started with Relative Economics in Aspen HYSYS”, Aspen Technology Inc. (2011).

Do you have questions or comments regarding this article? Click here to contact us.